The construction phase of PacWave South is nearing an end. The build of the medium voltage Utility Connection and Monitoring Facility (UCMF) on NW Wenger Lane started in February 2023 and should be completed in December 2024.

The installation of the PacWave terrestrial cables and subsea cables was completed in mid-October 2024. This was by far the largest and most complex part of the overall construction process and involved the installation of almost 50 miles of medium voltage cable using three vessels and a large remotely operated vehicle (ROV).

Construction of the underground components of PacWave was completed in mid-May 2022. Most of the activity was focused on the Driftwood Beach State Recreation Site area in Seal Rock, Oregon and involved horizontal directional drilling beneath the ocean shore to install cable conduits deep under the beach to the park, and from the park to the UCMF. Over 6 miles of conduit was installed.

If you wish to receive construction updates via email, or have questions or concerns, please send an email to [email protected].

LATEST UPDATES

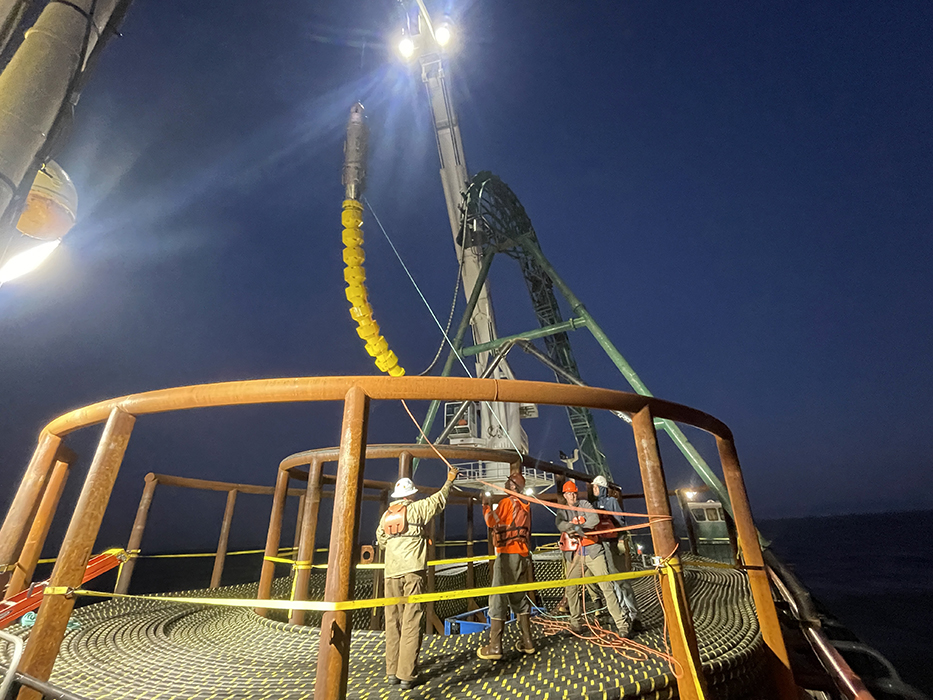

10/14/2024 – Just before 04:00 am on Sunday 10/13, the Nautilus ended its cable burial and post-burial survey operations and started back towards North Bend to start to demobilize. Since operations start in August, the cable burial ROV spent more than 980 hours on the seafloor!

The demobilization of the Nautilus brings PacWave’s cable installation field work to an end.

Thank you to the Nautilus crew for all their efforts during cable burial work. Also sincere thanks to Tom Ulrich (RTC’s onboard representative) and Carl Barrett from 3U Technologies (PacWave’s onboard representative) for their extended service on the Nautilus during the full 2+ months of the burial efforts.

We would also like to thank the other ocean users and our neighbors on land for your support and patience during this major construction operation.

Work at the UCMF will continue for another couple of months, so please check back here for further construction updates.

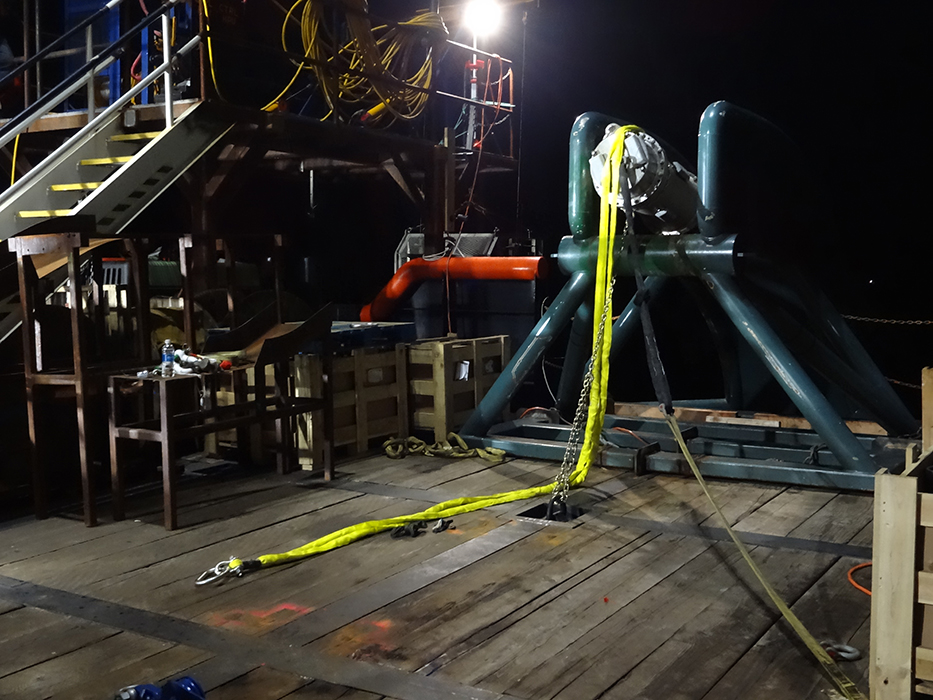

In my previous update, the Innovator crew were in the process of installing the last of the concrete mattresses used to stabilize the cables. We ran into some last minute technical issues that had us returning to Newport briefly before resuming mattress deployment on 09/08. At 5 am on 09/09 the last of the mattresses was deployed and, with the deck of the Innovator empty for the last time (photo 1), we headed back towards North Bend for the final time. As we cruised south, the team took a moment to reflect on the enormous undertaking that they had just completed safely and successfully (photo 2) before taking the opportunity to relax on deck (photo 3). The PacWave team would like to sincerely thank all those who worked so hard to make the cable installation operations such a success, especially Joshua Hankin-Foley, who was in charge of operations on the Innovator.

Once the Innovator arrived at the dock in North Bend on 09/10, many of the people on board started departing for home, or for the next project, while others remained on board to demobilize all the equipment and to return the vessel to the same state as it was in when it was first chartered back in early June. This work is just about to wrap up.

Meanwhile, the Nautilus (photo 4) has been continuing its cable burial operations using the CMROV 3 (photo 5). The control room from which the ROV operations are run is shown in photo 6. The burial work has been going well and included the ROV completing an uninterrupted 138-hour dive. That’s 5.75 days of continuous underwater work without resurfacing. This broke the Nautilus’ previous record and was celebrated with an ROV team photo (photo 7).

Despite this herculean effort, cable burial is a slow process, with up to three burial passes needed along the 40-plus miles of our subsea cables. So, this work is still going on. We are seeing some weather delays at the moment, but hope cable burial work will be completed in the next couple of weeks.

On the terrestrial side, work has gone well. All the terrestrial cables between the UCMF facility and Driftwood were installed without any issues and all the cables (both terrestrial and subsea) have been successfully tested. RT Casey has now completed their work and the parking lot at Driftwood Beach state park is fully reopened. We thank you for your patience.

Work at the UCMF is also progressing well. Now the site has power, the final touches are being made to the Control Building (photos 8 and 9) and final completion of the site is expected in the next couple of months.

09/05/2024 – Once all the cable lay equipment was removed from the Innovator in North Bend, the crew started loading 30 concrete mattresses and four cradles. The cradles were to be placed near to the subsea connectors out at the site. Later, the Nautilus will lift each of the connectors into its cradle. These cradles will keep the connectors up out of the sediment and reduce the risk of corrosion. Photo 1 shows the piles of mattresses in the foreground and the yellow cradles behind them.

By 08/26, the ship was ready to head back out to the site and to get back to work. However, the weather was not cooperating. Much of what we are trying to do onboard the Innovator requires relatively calm seas, as we are bringing equipment on and off the vessel. And as you likely know, the seas off Oregon are not often calm – which is why we are building a wave energy test facility here!

The ship finally left North Bend just after noon on 08/29 as the forecasts were for the seas to be trending down, and being on site allows us to quickly take advantage of available weather windows. However, conditions didn’t improve sufficiently until 08/31 and then some technical issues limited activities to using the ROV to survey the cable routes near the end of the conduits to determine where concrete mattresses might be needed.

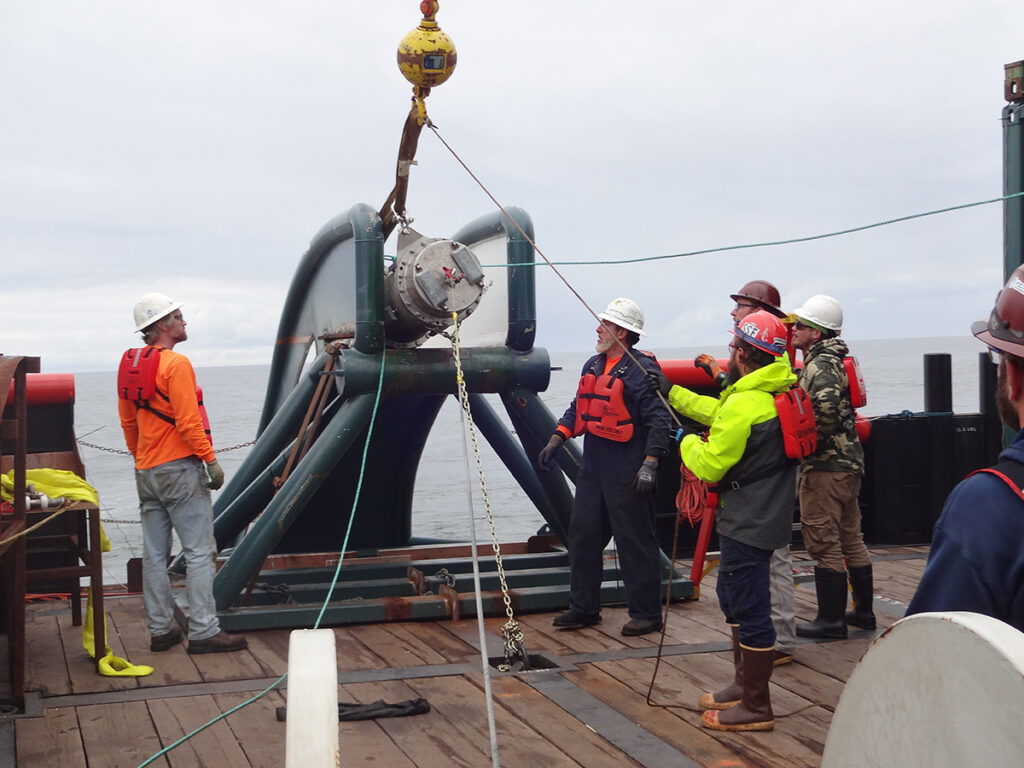

With a brief improvement in the weather on 09/01, the team rapidly deployed all four of the cradles. For each one, this involved stationing the ROV down by the subsea connector on the seafloor and then lowering a cradle down to the seafloor using the ship’s crane. The location of the cradle was monitored using the sonar and the cameras on the ROV. This gave the crew real time information on where the cradle was located in relation to the subsea connector, and by adjusting the position of the ship, moving the crane, and occasionally nudging the suspended cradle with the ROV, the crew could position the cradle on the seafloor. Photo 2 shows the ROV heading to the seafloor, and photos 3 and 4 show a cradle being deployed.

After another weather standby day, the Innovator started installing concrete mattresses on nearshore areas of cable 1 where cable burial has been less successful. From the multiple surveys we had conducted over the last few years, we were aware there was a section of the seafloor just seaward of the conduits in which it was going to be challenging to achieve good cable burial. The seafloor here shows significant sand movement – sometimes there is no sand, and at other times there are several feet of sand. The sand lies on rock and cobble that is difficult to trench. In these areas, where the cable is exposed, or partly exposed, we strategically place concrete mattresses to stabilize the cables. The concrete mattresses we are using are manufactured by SubMar.

The crew installed two mattresses on cable 1 on the morning of 09/03. This operation was similar to the cradle deployment with the ROV monitoring the placement of the mattresses from the seafloor. Additional work was not possible due to an issue with the onboard crane. This required the Innovator return to North Bend for repairs. These were completed and the ship once again headed to the site late in the afternoon of 09/05.

Back on site early on 09/06, the crew spent the day installing the remaining mattresses that are needed on cable 1. Photos 5 and 6 show the mattress deployment.

We are now starting to install the remaining mattresses and keeping our fingers crossed for workable weather. This should be the last task for the Innovator before demobilization.

Meanwhile the Nautilus continues to bury the subsea cables offshore.

On land, great progress is being made. After several delays, the switchgear for the UCMF was delivered and installed in the Switchgear Room by Safety Electric (see photo 7). Meanwhile the shoreside team from RT Casey have pulled all the cables between Driftwood and the UCMF and are now busy terminating the power conductors and fiberoptic elements (see photos 8 and 9).

08/25/2024 – On 08/19 we attempted to start the installation of cable #3, the last of our four cables. However the messenger wire was damaged and needed to be replaced. The operation was similar to what had been done with cable #1, which is described in an earlier post. While this was happening, the seas picked up and we decided to standby until the following day.

With a prolonged deterioration in the weather forecast to start on 08/22, it was critical that the cable lay operations went smoothly if we were to avoid several days of weather standby waiting to deploy the subsea connector. And as this was the fourth cable the crew had laid in less than 3 weeks, everything did go smoothly.

With the dive vessel on site at first light on 08/20, the Innovator started the messenger wire exchange at 10:00 am and by 2:00 pm the ¾” pulling wire was on board. A further 4 hours later, the end of cable #3 was onshore in the Driftwood vault and the crew aboard the Innovator started to install the split pipe as we laid the cable on the seafloor. By 8:30 pm all the required split pipe had been installed and the main lay was underway. Based on the experience gained with the previous cables, the Innovator was able to lay cable #3 faster than before – up to an impressive 0.8 miles per hour!

By 6:00 pm on 08/21 we were approaching the end of the cable route and prepared to deploy the subsea connector. For the first time, this was a daylight operation, which makes things slightly easier. And again, the crew’s experience with the deployment of the previous three connectors meant that this challenging operation was completed seamlessly, and quickly. By 8:15 pm the last of the PacWave South cables had been successfully laid and the subsea connector was resting on the seafloor.

Not surprisingly, there was an immense feeling of accomplishment for all those on board (other than the people who were sleeping during the exciting end to this phase of the cable installation!). By 10:30 pm we were starting our transit back to Coos Bay.

By 8:00 am on 08/22 we were tied up at the dock in North Bend and the crew started unloading equipment. At 10:00 am welding crews were on board cutting the cable storage tank off and removing it from the vessel. On 08/23, the gantry was lifted off onto the dock and was disassembled, to be used by RT Casey on a future project. As is always the case, demolition is much faster than construction, and by 08/24 there was little left on the deck of the Innovator to show what a huge operation the cable lay had been.

The Innovator is now being prepared for deploying concrete mattresses, which are additional cable protection we will use in areas where sufficient cable burial cannot be achieved.

Meanwhile the Nautilus has continued its burial operations.

08/19/2024 – Work offshore has continued to go well.

We completed the lay of cable #2 at about 4:30 am on Tuesday, 08/13. With two cables installed, the Innovator headed to Newport to pick up additional split pipe and offload trash etc. While in port she also took on water and additional groceries, including lots of coffee (we had been running low and that is not a good thing on a vessel where crews are working 24/7!). While at the dock there was an issue with the onboard crane, which required repair. Hornbeck Offshore Services quickly mobilized the people necessary to address the problem, but we had to remain in port a little longer than expected. The upside to this was that it gave those on board an opportunity to get out and about in Newport – running errands, grabbing coffee or a meal etc. It also gave us an opportunity to host staff from the Office of Representative Val Hoyle and some off our colleagues including Bob Cowen, the Director of OSU’s Hatfield Marine Science Center to show them the Innovator and explain what we are doing in more detail.

We departed Newport at 3 am on 08/15 and started to install cable #4 just before noon. Despite the fact that every time the crew lay a cable, the operation gets smoother and faster, the cable lay wasn’t completed until the morning of 08/18. The reason the overall cable lay operation has been slow for cables #2 and 4 is that the weather has not been ideal. As safety is of paramount importance in an operation like this, we have established limits on the weather conditions in which specific activities can be conducted and if conditions are not favorable, we go onto weather standby. While being on standby is very expense for PacWave, there is nothing more important than the safety of the personnel involved, the vessels, the cable and connectors, and the environment.

Due to the sea conditions, the Innovator sat near our subsea connector deployment location for almost a day before finally finishing the lay of cable #4 at 4:20 am on 08/18. With weather again deteriorating to a point that we couldn’t start our final cable (cable #3), the Innovator returned to Newport.

At just after midnight this morning ,we left Newport and returned to the conduit location off Driftwood Beach state park. We were greeted by 4-5 foot seas with occasional 6-foot swells – too much for us to continue our operations. However, we were also greeted to a beautiful sunrise and the first time that all three of our vessels were in the same location (the Liberty, Nautilus and Innovator). The Liberty has continued to provide dive support for the Innovator operations, and the Nautilus commenced cable burial operations on 08/15.

We hope to start the lay of our final cable tomorrow.

(Photo: Mark Farley)

08/11/2024 – Picking up where we left off on the previous update, the team aboard the Innovator continued the main lay of cable #1 through to about 10:00 pm on 08/05, when we reached the location where we planned to lay the subsea connector on the seafloor within the southern berth of the Pacwave South test site. This operation is called the “wet park” and is one of the most challenging parts of the cable lay operation.

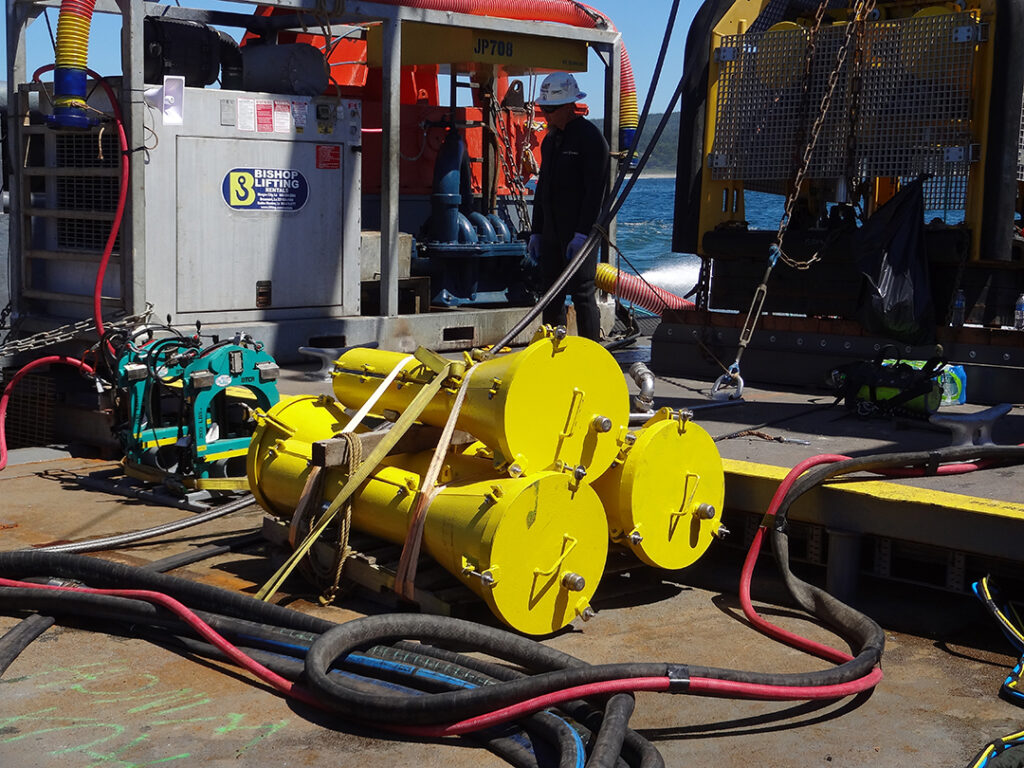

The subsea connector weighs 625 kg (or 1,378 lb.) and the bend restrictors associated with it add an additional 360 kg (794 lb.). A photo of two of our subsea connectors and their yellow bend restrictors can be found in the 07/29 update below.

Using the vessel’s crane, the connector and bend restrictor assembly was lifted up and over the cable gantry and lowered onto the stern chute. It was then lowered to the seafloor using a deck winch. Once in place, the ROV released the winch wire from the connector by triggering a Green Pin spring release ROV shackle which, despite a couple of minutes of concern, worked as designed. With that, the lay operations of PacWave’s cable #1 were completed. Celebrations were a little muted as the whole wet park operation had taken almost 5 hours and was completed at 2:50 am on the morning of 08/07 and everyone was tired.

Next up was cable #2, but as the afternoon weather conditions were not conducive for the wire pulling on conduit #2, the Innovator headed to Newport to allow the representative from Makai Ocean Engineering to disembark and for some spares to be delivered.

We remained in Newport until 12:30 am on 08/08, when we headed for the conduit punchout location in the hope of starting on cable #2. However, the seas did not settle down as quickly as we had hoped, and no work was completed that day.

Overnight the seas calmed, and the morning of 08/09 was ideal for at sea operations. However, some technical challenges delayed the start of work until 2:30 pm. Despite this, the messenger wire-to recovery wire-to pulling wire exchanges were completed in record time (a little over 4 hours, compared to over 8 hours for conduit #1) and the day ended with everything in place to start pulling cable #2 to shore the following day.

Pull in of cable #2 to the vault at Driftwood commenced at 8:30 am on 08/10. Once again, operations were significantly faster than the previous time with it taking a little over 9 hours from the start of the cable pull in to having all the split pipe installed and the Innovator commencing the main lay. Previously, this took over 13 and a half hours.

The Innovator continued the main lay overnight and at 9:15 am, about 45% of the cable was on the seafloor. We are continuing the lay operations and hope to have the lay of cable #2 completed sometime on Monday.

UPDATE: Our Offshore Support Vessel Nautilus arrived in North Bend today. The ACSM-owned and operated vessel is permanently equipped with a work class remotely operated vehicle (WROV), the CMROV3, which will be used to trench in our cables. Photos courtesy of Kim & Rob Thompson, RT Casey.

08/05/2024 – After a slight delay, the Innovator left North Bend at about 6:30am on 08/01 and headed to the seaward end of the conduits, which we installed back in 2021/2022 and which run deep under the seafloor out from Driftwood Beach state park. The vessel arrived on site mid-afternoon and we began our sea trials.

Sea trials are basically a dry run of the activities that will be needed to install the subsea cables. This allows for the various teams on board to establish clear communications, which are critical for an operation such as this, and to ensure that all the necessary equipment is functioning correctly. This included the remotely operated vehicles (or ROVs), which will often be our eyes, and sometimes hands, on the seafloor and the Innovator’s dynamic positioning system (or DP). DP is a computer-controlled system that uses the vessel’s thrusters and propellers to automatically maintain its position and heading without the need for anchors or mooring lines. The Innovator is DP2, which means it has a redundant backup system in case the primary DP system fails.

The sea trials also allowed for the 39 people on the Innovator to get into the daily routine on board. There are 14 officers and crew from Hornbeck Offshore Services (the company that owns and operates the vessel), an excellent three-person catering team, and 20 of us that make up the project team. This includes RT Casey personnel, as well as people from Tetra Tech, Reliant Robotics, Vision Subsea and Sause Marine Services. The final two on board are observers from Makai Ocean Engineering and PacWave. As operations are running 24 hours a day, some people are working from midnight to noon, others from noon to midnight, and a couple of us on a slightly more regular schedule.

On 08/02, the team of divers operating off the Liberty opened up conduit #1, which had been sealed up last year. They also prepared the 3/16-inch “messenger wire” that had also been installed last year. Ultimately the subsea cables will be pulled into the conduits from the ship to the vault at Driftwood using a winch in the parking lot equipped with a ¾-inch steel “pulling wire”. To get the pulling wire through the conduit and out to the ship takes a few steps. First, the Innovator recovers the messenger wire and attaches it to a 3/8-inch “recovery wire” on a winch on deck. The winch at Driftwood then pulls the recovery wire back through the conduit to Driftwood. Here the pulling wire is attached and that is then pulled through the conduit back to the Innovator where it can be attached to the subsea cable. Once that is done, the cable can be winched to Driftwood through the conduit using the pulling wire.

On 08/03, the Innovator recovered the messenger wire from near the end of the conduit, attached it to the recovery wire and, at about 8:00am, the onshore crew at Driftwood started winching it in while the crew on the Innovator paid out wire. About 3 hours later, when the recovery wire had made it about 95% of the way through the conduit, the messenger wire parted, which is another way of saying that it broke. The crews recovered the wires from either end of the conduit and assessed the situation.

It was decided that the onshore crew would pig the conduit again, pulling another messenger wire. For details of the pigging process, check out the Construction Update below from 8/15/2023. This was successfully completed and the vessel and crews called it a day and planned to try again the following day.

Most of 08/04 was taken up pulling the messenger wire (slowly and cautiously, but successfully) and pulling the ¾-inch wire through the conduit. This too was done successfully and the wire was left at the seaward end of the conduit attached to some buoys.

And early this morning, the crews on the Innovator and onshore started preparing for the pull in of the subsea cable from the Innovator to Driftwood. A significant milestone was reached at 08:25 am when the shoreside end of cable 1 was pulled off the Innovator and into the ocean.

Pull in of the first subsea cable into conduit 1 continued until about 1:15pm when the RTC crew on the Innovator started installing articulated pipe, or split pipe, on the outside of the subsea cable. Split pipe is a ductile iron, clip together cable protection system developed to provide shallow water abrasion and impact protection for subsea cables. This is being installed along the cables where they exit the conduits as it is known that there are some areas where complete cable burial may not be achieved. Just after 4:00 pm, while the RTC crew onboard continued to install the split pipe, the subsea cable reached the vault at Driftwood. Once it has been secured in the vault, the RTC onboard crew will continue to install split pipe until the required length of cable has been covered. At that point the Innovator and RTC team onboard will continue to lay cable along the designated route to the offshore test site, guided by the team from Tetra Tech.

07/29/2024 – The Innovator arrived in Coos Bay a little after noon on the 27th. Dan Hellin from PacWave joined the vessel on the 28th and will be onboard for the next several weeks through the cable lay operations. For the PacWave team, this was the first opportunity to see the subsea cables up close and to marvel at the sheer volume of cable there is on board. The photographs below do not do it justice.

On the end of each cable is one of the subsea connectors manufactured by MacArtney. These are lashed down to the deck until it is time to deploy them.

While the photo of the stern of the vessel shows a lot of equipment already installed, a key piece of equipment that needed to be lifted into place by two cranes was the gantry, which will feed the cables up and over towards the chute on the stern of the vessel. While this was a highly complicated lift, it was performed seemingly effortlessly by the teams from Sause Marine Services and RT Casey. The gantry is now welded in place and mobilization of other equipment and provisions continues. We hope to leave Coos bay within 48 hours to conduct sea trials before starting cable lay operations. Let the fun begin!

07/27/2024 – The HOS Innovator is expected to arrive in Coos Bay this afternoon and, after some additional mobilization work and reprovisioning, it is expected to start subsea cable installation work in the next few days. In preparation for this, the M/V Liberty completed a series of grapnel runs designed to remove any marine debris from along the cable routes. A couple of derelict crab pots were recovered and the team from RT Casey coordinated with Oregon Department of Fish & Wildlife (ODFW) to try to track down the owners to see if they wanted them. The first two photos below show the Liberty alongside the Port of Newport’s International Terminal and off Driftwood Beach state park.

While preparation for the subsea cable installation is underway, work on the terrestrial cables has also commenced. The parking lot at Driftwood is partially closed to allow for the cable work. However some parking, including ADA parking, remains available, and access to the restrooms, the viewing platform, and the beach will be maintained at all times. However, RVs, trucks and trailers should not use Driftwood Beach state park while work is underway as there is nowhere for large vehicles to turn around. Work is expected to be completed by late September.

The terrestrial cables were delivered to the UCMF site on NW Wenger Lane (see photos below) and yesterday the first of the terrestrial cables was successfully installed (see photos and a brief video clip below).

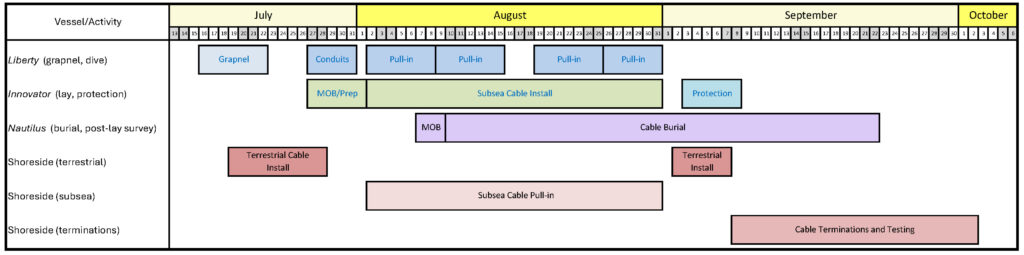

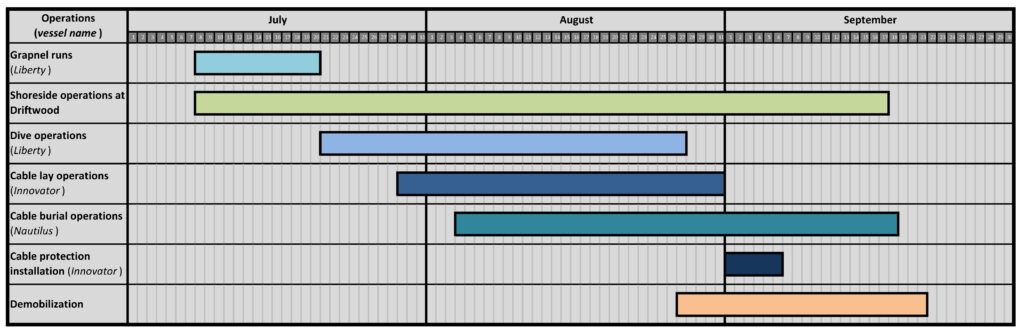

While it remains subject to change, the general schedule of work over the next few months is shown below.

07/15/2024 – The Nautilus and the HOS Innovator transited the Panama Canal on Friday and Saturday are now heading up towards Coos Bay. Below are some photographs of the Innovator at the Pedro Miguel Locks (thank you for the photos, Haley!) and a timelapse of the Innovator from the webcam at the Miraflores Locks – the final locks before the Port of Balboa and the Pacific Ocean.

07/01/2024 – The HOS Innovator, with cables onboard, in Port Fourchon LA waiting for Hurricane Beryl to clear the area before heading to the Panama Canal and on to Oregon.

06/26/2024 – Construction at the UCMF continues and the final phase of PacWave South construction is about to get underway.

UCMF Build: Gerding Builders work at our UCMF site on NW Wenger Lane has gone extremely well and substantial completion is expected in the next few months.

Cable Manufacture & Shipping: The team from RT Casey has been busy managing our cable manufacturing and planning for our cable installation work, but much of this has been happening elsewhere – hence the lack of regular updates!

As previously mentioned, the manufacture of our subsea and terrestrial cables was completed in Rognan, Norway by Nexans. The terrestrial cables were shipped to Seattle and are now in storage before they will be transported to the UCMF in July.

The subsea connectors, which go on the seaward end of the subsea cables, were successfully installed by MacArtney in Rognan. Everything was then fully tested before being loaded aboard the 450-foot freighter Frieda, which set sail from Rognan on May 27, 2024 bound for the US.

Seventeen days later, on June 13, the Frieda arrived in Port Fourchon, Louisiana and is currently transpooling the cables onto the HOS Innovator, a 240-foot multi-purpose service vessel (MPSV), which will be our cable lay vessel. This vessel should depart for Oregon (via the Panama Canal) around the end of this month.

Cable Installation: Cable installation operations are scheduled to start in July and run through September. Work will consist of shoreside operations at both Driftwood Beach State Park and the UCMF site in Seal Rock, and offshore operations involving the HOS Innovator, the 246-foot offshore support vessel OSV Nautilus, and the 89-foot general motor vessel M/V Liberty. The HOS Innovator and the Nautilus will be operating out of Coos Bay, and the Liberty will be operating from OSU’s dock in Newport.

The cable installation and burial operations are being conducted by R.T. Casey at Driftwood, the UCMF and from offshore of Driftwood Beach State Park in Seal Rock, and out to 13 miles offshore (click here for a PDF flyer showing the work area).

A general schedule is provided below. Please note that all dates are subject to change due to weather and other factors.

Logistics

- Offshore operations will be 24 hours a day, 7 days a week.

- Offshore operations will be staged from the HOS Innovator, M/V Liberty, and OSV Nautilus. Vessels can be reached on VHF Channels 13 & 16.

- Mariners are requested to contact the above listed vessel and maintain a minimum of 500 yards distance from vessels involved in the cable installation work when transiting in the vicinity.

- The parking lot at Driftwood will be partially closed for construction starting on July 8. However, parking will remain available, as will access to the beach, the restrooms and the viewing platform.

- Work at Driftwood and the UCMF will be daylight only operations, but will occur 7 days a week.

- For additional information contact: Zachary Casey at (504) 491-2288.

June 2, 2024 – Loading of the subsea cables onto the freighter Frieda was completed ahead of schedule and the vessel departed Rognan, Norway at 19:52 UTC (12:52 PT) on May 27. As you can see from the Google Earth image below, the freighter is now a little over half way across the Atlantic and is continuing on towards Port Fourchon, Louisiana. ETA is currently on June 13.

May 24, 2024 – A significant milestone was just reached with the arrival of the freighter Frieda in Rognan, Norway on May 21. The 452-foot cargo ship is currently alongside the Nexans quay and almost 48 miles of subsea cables are being carefully spooled from shore and onto the vessel before it starts the journey to the US on May 29. There they will be transpooled onto our cable lay vessel in Louisiana before starting the final leg of their journey to Oregon where they will be installed between PacWave South and Driftwood Beach State Park in Seal Rock, Oregon.

Lots more to come on this in the next few months!

Thanks again to the RT Casey team for their lead on the procurement, transportation and installation of all the cables and connectors for PacWave South.

March 9, 2024 – Great progress continues to be made at the UCMF site by Gerding Builders and their team. As you can see from some of the top left and top center photos, the site is really beginning to take shape. The second of our two PMEBs, the very large Power Conditioning Building, is currently being erected (top right). The siding on the Switchgear Building is now installed (bottom left) and interior work in underway. Work is also continuing on the Control Building (bottom middle), where the crews are busy installing drywall and getting everything ready to start painting. The photo on the bottom right shows the front lobby of the Control Building with Kalwall panels around the top of the room. These were a great recommendation by our architects – HGE Architects.

January 4, 2024 – The first of our two pre-engineered metal buildings (PEMBs) arrived on site on January 3rd and the crew immediately started to erect the structure. They hope to have it completed by the end of the month, with the second PEMB arriving around February 12th.

Work on the underground vault has also progressed – the floor of the vault has been poured, and the walls and lid are scheduled to be poured next week.

December 22, 2023 – After an early start, and a late end to the day on Wednesday, the slab for the large Power Conditioning Building was successfully poured. As the building measures 140 by 70 feet, it took a lot of concrete. The original plan had been to split the pour over 2 days, but the decision was made to take advantage of some great weather and to do it in one day. This was the last large concrete pour before the spring.

Elsewhere on site, progress has been good. Work has started on the underground vault where the conduits that run from Driftwood Beach State Park to the site will terminate. The 20 by 14-foot vault can be seen a little above the freshly-poured Power Conditioning Building slab in the picture on the right, below. This should be completed early in the New Year.

In early January, the first of two pre-engineered metal buildings will arrive on site. This will be the Switchgear Building. The Power Conditioning Building will follow a month or two later. Once those two buildings are erected, the final site layout should really take shape.

Work will be continuing over the holiday period, but at a reduced pace as many of the contractors will be taking a well-earned break. Things will ramp up again significantly in the first week of January.

Manufacturing of the subsea and terrestrial cables is nearing completion in Norway, and factory acceptance testing is expected to occur in February and March of next year. The cables should ship to the US in April.

Happy holidays to all.

October 20, 2023 – Work has continued to progress well at the UCMF. Paving of NW Wenger Lane was completed successfully in early September and, as the photographs below show, the Control Building is taking shape. The walls and roof are nearing completion and rough-in work is well underway.

Elsewhere on site, the slab for the Switchgear Building has been poured and the footings for the large Power Conditioning Building are in place. Both these buildings will be pre-engineered metal buildings (PEMBs), and these are expected to be installed in the next few weeks.

Meanwhile, the fabrication of subsea and terrestrial cables is nearing completion. Factory acceptance testing (FAT) of the cables and splicing of the cable connectors will occur in Norway early in 2024, before everything is shipped to the US. Cable installation is expected to begin in mid-June of next year.

September 2, 2023 – The previous update from August 15th ended on a positive note about the ongoing offshore work, as sea conditions were improving, and we hoped to resume dive operations that afternoon. Unfortunately, diving could not safely restart until the morning of the 16th and by the morning of the 17th, we were once again experiencing unworkable sea conditions. These conditions persisted for several days. On the night of August 20th, nearby wave buoys were reporting significant wave heights of over 11 feet and the Seacor Lee was experiencing waves larger than that. While it was a somewhat bumpy ride for a while, everyone onboard took the opportunity to catch up on sleep, movies, reading and work. A brief video taken on the morning of August 21st gives some idea of the sea states. It was taken with a drone, so the camera was stationary, and only the ship was moving.

The several days of weather standby also meant that work at Driftwood was put on hold, as that work was directly linked to the dive operations. However, by late afternoon on the 21st, dive operations resumed and by the evening of the 22nd, the seas were flat calm. Sea conditions remained ideal for dive operations for the next several days, allowing the dive team from American Marine to complete all the planned work by early afternoon on Sunday, August 27th, putting us a couple of days ahead of schedule.

At noon on August 28th, the Seacor Lee docked at the International Terminal in Newport to offload some equipment, swap out personnel, and restock with water and provisions, before heading back out to sea on the 29th to conduct a few days of additional survey work along our planned subsea cable routes. This was also successfully completed on schedule.

With offshore dive operations complete, the crew at Driftwood replaced the lids on the vault on the 28th and started packing up their equipment. By September 1st, everything had been removed from the parking lot.

While a lot of activity has been happening offshore and at Driftwood over the previous few weeks, great progress has continued to be made at the UCMF site. The Control Building is taking shape with framing and work to install the roof nearing completion (below left). The slab for the Switchgear Building is scheduled to be poured at the end on next week. However, what will probably please those who live on NW Wenger Lane the most is that the road will soon be paved. The roadbed has been prepared (below right) and paving is currently scheduled for next Wednesday (September 6th). To facilitate this, we are asking people to avoid, or minimize, using Wenger Lane that day to allow the paving company to complete the work as quickly as possible.

August 15, 2023 – The dive team successfully cut back the water-filled southernmost conduit and installed a bellmouth on the end of it (the photograph on the left shows one of the conduits being filled with water in the Driftwood vault). Once the bellmouth was in place, the shoreside team launched a “pig” down the conduit from the vault. The middle photo shows one of the pigs. This is sized to fit snugly inside the conduit and it is then forced down the length of the conduit using pressurized water. As the pig travels down the conduits, it pulls a messenger wire with it. This messenger wire will be used next year to pull in a thicker cable, which will in turn be used to pull in our subsea cable. The photograph on the right shows the “pig launcher” attached to the conduit. The messenger wire can be seen coming out of the end of the pig launcher (the Driftwood photographs were taken by Nathaniel Casey and Carl Barrett). About 75 minutes after the pig was launched, it arrived at the seaward end of the conduit, where it was recovered by a diver. The diver then secured the messenger wire to a cover that was installed on the bellmouth to ensure sediment does not enter the conduit between now and when we install the subsea cables next year.

By late yesterday morning the offshore conditions had begun to deteriorate and dive operations were suspended. By the afternoon seas were occasionally reaching 10 feet, and increased overnight. The seas dropped significantly this morning and we hope to resume operations this afternoon if we can do so safely. The photographs below show the stern of the Seacor Lee bouncing up and down in the swell yesterday.

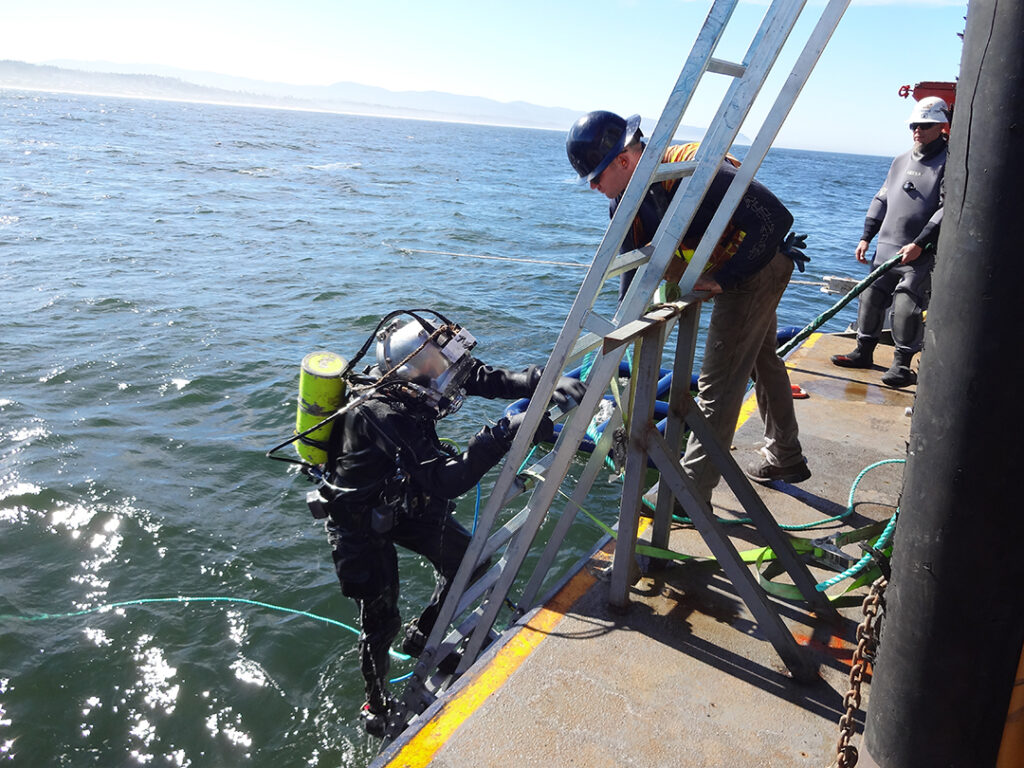

August 13, 2023 – It has been a busy couple of days at Driftwood and aboard Stabbert Maritime‘s Seacor Lee. On land, the team from RT Casey have been preparing the conduits in the vault at Driftwood. The vault lids were removed on the 10th and the conduits have been depressurized and filled with water in preparation for the next stage of operations. Offshore, the dive team from American Marine International have been spending hours on the seafloor preparing the end of the southernmost conduit (HDD #4). The dive team consists of a diving supervisor, a working diver, a standby diver, a tender for the working diver and a tender for the standby diver. Diving off the stern of the vessel, using surface-supplied Nitrox (sometimes called Enriched Air Nitrox), a working diver can spend well over 2 hours on the seafloor on each dive. With four divers, we can have someone working on the seafloor for about 10 hours per day. All dive operations are controlled by the dive supervisor located in the “Dive Shack” and everything is coordinated with those on the Bridge of the Seacor Lee.

Photos (clockwise from top left): a view of Driftwood from the vessel; the dive team prepping a diver; a diver climbing up the ladder back onto the vessel; the dive supervisor monitoring a diver from the “Dive Shack”; four yellow “bellmouthes”, which will be installed on the end of each conduit a view of the Bridge from the deck.

August 11, 2023 – The 265-foot offshore support vessel the Seacor Lee arrived in Newport a little after 8:00am yesterday morning and tied up at the Port of Newport’s International Terminal for a few hours to load additional personnel. Thanks to Don Moon and his team for the smooth operations. Shortly after 2pm, with everyone safely onboard, the vessel departed for the worksite.

After have set anchors, and with the the vessel sitting above the punchout location of conduit #4, everyone grabbed some dinner and settled in for the night.

After breakfast at 5:30am this morning, the dive crew met to discuss the day’s operations and at 8:16am, the first diver entered the water.

July 31, 2023 – Construction work has been focused on our Utility Connection and Monitoring Facility (UCMF) site at 1110 NW Wenger Lane (our official street address). This work obviously impacts the immediate neighbors, but is less of an issue for others. However, Gerding Builders have been making great progress as you can see from the photographs below.

While the focus has been on out terrestrial site, things are about to change as you will see from an OSU Press Release that came out today. Starting at the end of this week, we will again have work going on at Driftwood Beach State Park and just offshore at the seaward end of the conduits we installed in 2021/2022.

The work at Driftwood will be much less impactful than the conduit installation work we conducted previously. Starting on August 4 or August 5, we will be setting up construction fencing around the vault in the Driftwood parking lot. The parking lot itself, the beach access and the restrooms will remain open, but parking may be limited, and some larger recreational vehicles may not be able to turn around. For larger vehicles, parking and beach access is available at Governor Patterson Memorial State Recreation Site located 3 miles south of Driftwood.

The focus of the 2023 work is the preparation of the four offshore conduits for the cable installation, which is scheduled for the summer of 2024. This summer we will be depressurizing and opening our conduits, including opening the seaward ends. Work on the seaward end of the conduits will require commercial divers and they will be working off the 265-foot offshore support vessel the Seacor Lee. The vessel will be anchored above the seaward end of our conduits, so it should be quite a sight from shore.

The divers will be cutting off the end of each conduit and installing a cable duct (or bellmouth) on the end. Once these are installed on all four conduits, a wire messenger line will be installed from the vault in Driftwood to the seaward end of each conduit. These will be used to pull the subsea cables into the vault at Driftwood next year. Once the messenger lines are installed, the conduits will be resealed and the vault in Driftwood will be closed up again, ready for the cable installation in 2024.

The 2023 work at Driftwood is expected to be complete by early September.

June 9, 2023 – Construction is well underway at the UCMF site. Much of the underground work is complete and Gerding Builders are looking to pour the slab for the control building early next week. This is the yellow building footprint in the photographs taken on June 6.

The manufacturing of our cables in Europe remains on schedule and planning for the 2024 installation of the cables is on-going.

April 23, 2023 – Over the last year or so, we have been focused on the procurement and contracting associated with the final two stages of construction: the build of our Utility Connection and Monitoring Facility (UCMF) in Seal Rock, and the manufacturing and installation of our cables.

On the cable front, we contracted with R.T. Casey to oversee the procurement, manufacture, and installation of our cables. The cables themselves are currently being manufactured by Nexans and the connectors, which will be fitted to the seaward end of the cables, are being manufactured by MacArtney. The cable and connector manufacturing is happening in Europe and the cables will be shipped to the US in about a year’s time for installation in the summer of 2024. OSU issued a press release about this in January.

OSU has also contracted with Gerding Builders for the UCMF construction. Equipment was mobilized to the site last week and construction is now underway. This work is expected to continue into early 2024.

February 4, 2023 – Construction of the PacWave medium voltage Utility Connection and Monitoring Facility (UCMF) on NW Wenger Lane in Seal Rock, OR will be starting soon. The facility was designed by HGE Architects and Gerding Builders have been contracted to lead the work.

07/18/22 – OSU issued a Request for Proposals for the construction of PacWave’s Utility Connection & Monitoring Facility in Seal Rock, OR. Note: this solicitation closed on 08/16/22.

05/15/22 – The “Park Closed” signs on Highway 101 should be coming down tomorrow, May 16, 2022, indicating that Driftwood Beach State Recreation Site has fully reopened. We thank all the neighbors for their patience and understanding during the construction activity.

05/12/22 – On Tuesday 5/10, with a small break in the weather, we managed to get the Driftwood parking lot and access road striped, and host a BBQ on site. There was a great turn out, with the majority of people coming from the neighborhood. The event was also an opportunity for project partners from State Parks, Oregon State University, The HDD Company and Jacobs to join most of the PacWave team to see the new park renovations.

In the next few days, we will be wrapping up our work and preparing to hand the park back over to State Parks to reopen. Our remaining work is focused on the underground vault itself. So, while the park remains closed to vehicles, pedestrian visitors no longer need to use the temporary trail off the access road. If there is work going on in the park, please avoid the immediate area and any equipment in the parking lot.

State Parks are getting the restrooms up and running again. These will hopefully reopen early next week, and the temporary portable toilets will be removed. At that point, the park should be fully reopened. Stay tuned for the exact reopening date!

05/05/22 – The Road & Driveway Company from Newport, OR did a great job repaving the parking lot and access road at Driftwood yesterday. As soon as the weather cooperates, striping work will get underway. The park remains closed to vehicular traffic, but pedestrian access to the beach via the temporary trail off the access road can resume. There is still some construction work underway, so visitors should remain careful when using the park.

05/02/22 – Over the next two days, Road & Driveway will be paving the access road and parking lot at Driftwood Beach State Park. For safety reasons, and to allow the asphalt to cure, Driftwood Beach State Park will be closed to pedestrians from 6:00am to 6:00pm on Wednesday, May 4.

We apologize for the inconvenience.

Note: the park remains closed to vehicular traffic at this time.

05/01/22 – Civil construction work at Driftwood has continued to go well. The underground cable splice vault has been completed and the area around it was backfilled. This allowed for the final sections of curb and sidewalk to be poured and work to start on grading and putting down base rock for the parking lot. This too is nearly complete, and paving is expected to happen this week (weather permitting). As the access road will also be repaved, the park will need to be closed to pedestrian access temporarily while the asphalt cures. We will post a notice on this webpage and post signs at the park. We expect the closure to be short.

After the vault was finished, we spent several days drying out the offshore conduits. This involved flushing them with dry, hot, pressurized air several times until they were sufficiently dry. They were then filled with nitrogen and sealed to prevent corrosion. They will remain this way until they are opened up again during the subsea cable installation phase of construction.

Once the conduit dry out was complete, the lids to the vault were carefully lowered into place. These will also remain in place until the subsea cables are installed.

We hope to be able to reopen the park later this month.

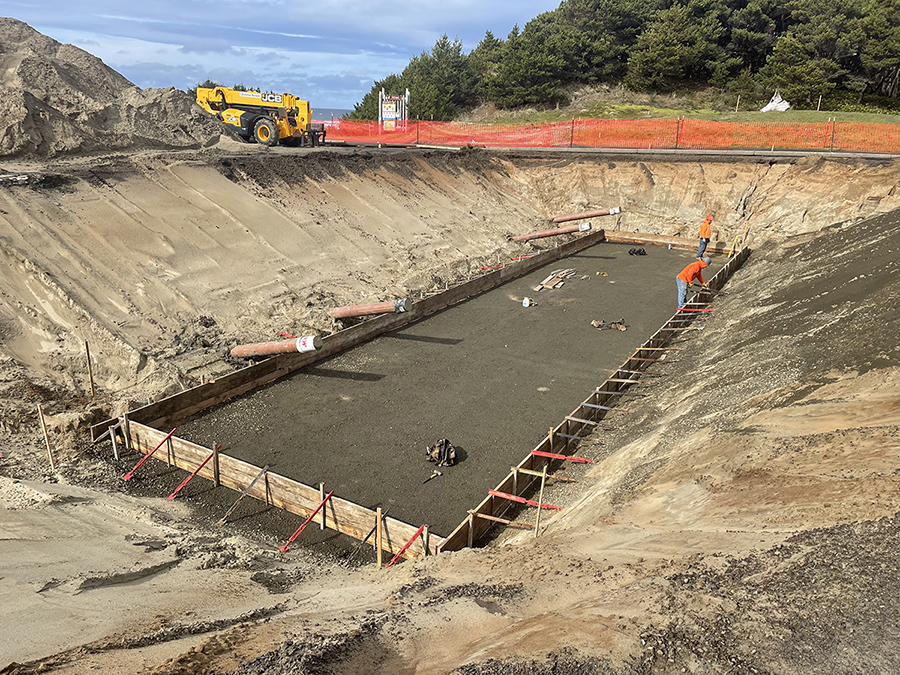

04/13/22 – In the last couple of weeks construction of the large underground cable splice vault at Driftwood Beach State Park has largely been completed by RK Construction. On 04/01, almost 110 cubic yards of concrete were pumped to form the foot-thick walls, and the concrete pour for the roof is scheduled for later this week, weather permitting.

In the last few days, KSH Construction have been busy backfilling around the vault, so it is quickly disappearing underground, and the large pile of sand from the excavation that has been sitting at the western end of the parking lot is rapidly disappearing as well.

The crews are also preparing to connect the terrestrial conduits to the eastern side of the vault in the next day or so. So those too will be disappearing underground.

Work on the improvements to the Park has also continued. More sidewalks have been poured and the handrail for the new viewing platform is now in place. Removal of the remaining asphalt in the parking lot should start next week and will be followed by grading and repaving.

03/27/22 – Work on the underground vault at Driftwood has been progressing well, as you can see from the photographs below. Its size is impressive. As is the amount of concrete and rebar, which is needed to construct it. The concrete work is being done by RK Construction, out of Otis, OR.

The vault floor has been poured and the formwork for the walls is nearing completion. We expect the foot-thick walls will be poured this week. Incorporated into the western wall of the vault are the four mounting plates for the steel conduits that run out to sea. Steel sleeves are being installed in the eastern wall, which will connect to the HDPE conduits that run to the UCMF site on NW Wenger Lane. The concrete lids for the vaults were also delivered last week.

RK Construction and KSH Construction have also been working on some of the improvements to Driftwood Beach State Park. Pedestrian visitors to the Park will have been using the newly built pathway running from the restroom building down to the beach access. Other work includes the installation of new gutters and catch basins, which will fix the drainage issues that previously occurred after heavy rains.

In addition to these improvements, a new viewing platform has been built by the southwest corner of the parking lot, which will provide great views over Driftwood Beach and out over the ocean for those who don’t want to venture down to the beach itself.

Civil construction work will continue at Driftwood for a few more weeks as we complete the vault, finish the renovations to the Park, and resurface the parking lot.

03/03/22 – The horizontal directional drilling (HDD) phase of the PacWave South construction is now complete, and all the underground cable conduits have been installed. The drilling crews, some of whom had been here since the end of May last year, have returned home or moved on to the next project.

The HDD and conduit installation operations were a major design, engineering and construction undertaking:

- Each of the four offshore HDD bores was over a mile long

- These bores ran up to 120 feet below the seafloor

- A total of 6.2 miles of cable conduit were installed below ground

- Almost 1.3 million pounds of steel and 60,000 pounds of high-density polyethylene (HDPE) conduit were installed to accommodate the PacWave South cables

With drilling complete, the focus has shifted to the civil construction at Driftwood. The first order of business is the installation of the underground vault, which will be where the subsea cables will transition to terrestrial cables. The vault itself will be large (approximately 74 by 17 by 10 feet) and requires a very large pit to be dug for it to be fabricated. The vault itself will be poured in place, with pre-cast lids. The vault excavation has been the primary focus at Driftwood over the last couple of weeks. The work is been done by the KSH Construction Company, out of Keizer, OR. Today they will start putting down some base rock under where the vault will be located. Construction of the vault will take two to three weeks to complete.

KSH is also working to rebuild the pathways near the Driftwood restrooms. Pedestrian visitors to the beach are reminded to avoid construction areas, follow instructions from any construction personnel and be careful near the work site.

There should be minimal activity at the UCMF site for a while. When conditions dry out a bit, the road will get repaired. Construction of the facility itself will likely start later in the year.

02/13/22 – It has been a busy, but successful few weeks.

Drilling operations for the terrestrial bore restarted on 01/17 and the intercept between the bore from Driftwood and the bore from the UCMF was made on 01/19. Once the intercept had been achieved, the last section of the borehole was opened up to its final 28-inch diameter. This was completed on 02/05 and was followed by a series of swab passes through the completed borehole. These swabs removed any remaining debris from the borehole prior to the start of operations to pull the conduits into the hole.

The terrestrial conduits consist of a bundle of four, 6-inch plastic conduits (specifically, high-density polyethylene, or HDPE) and one 2-inch HDPE conduit. Each conduit is about 2,400 feet long. The bundle of conduits was strung out on a series of rollers at the UCMF side of the borehole and was then pulled into the hole using the drill rig located at Driftwood. This operation, commonly called a “pull back”, started late on 02/08 and was completed late on 02/10. Much like the offshore conduit installation, there was a risk of the conduits getting stuck in the borehole, especially as they got further down the hole, which necessitated some long days. Ultimately, the pull back was completed without any problems and concluded the drilling operations for PacWave South.

Once installed, a foam “pig” was run through the full length of each conduit to clean it. Each pig also pulled a length of high-strength mule tape through the conduit. This mule tape will later be used for pulling the cables through the conduits.

The final steps to complete the terrestrial bore will be to grout both ends of the borehole and run a final “gauging pig” or “mandrel” through each conduit to ensure the final installation meets the project requirements.

While the terrestrial bore operations have been underway, civil work has started at Driftwood. Initial work involves improvements to the pathways around the restrooms. Now that the drill rig has been demobilized off site, the focus will shift to the parking lot area where a large splice vault will be constructed underground prior to the rebuilding of the sidewalks and the parking lot itself.

01/04/22 – It has been quiet at both Driftwood and the UCMF sites over the holiday season as the crews took a well-earned break.

Prior to the holidays, great progress was made on the terrestrial bore, but the work is not yet complete. We are within a few feet of making the intercept between the Driftwood bore and the UCMF bore, and have reamed almost 75% of the total bore to its final diameter in preparation for the installation of the cable conduits. However, we have encountered some gravel and cobble geology that was not expected, and this is creating some challenges. While not an uncommon occurrence, it means that the project team are reassessing how to most effectively address the issue. When drilling through gravel and cobble, there is a risk that drilling mud (a non-toxic mixture of water and bentonite clay) can escape into the geology. It then has the potential to make its way to the surface. Unfortunately this occurred just before the holiday break when some drilling mud appeared in the bottom of Friday Creek, just south of the Driftwood parking lot. The HDD Company quickly identified the issue and the location of the mud, and drilling was stopped immediately. The amount of drilling mud that reached the surface was small and has largely dissipated due to the heavy rains. OSU and The HDD Company personnel are working with staff from Oregon State Parks and other agencies to develop a plan to move forward, and a natural resource specialist has been monitoring the area over the holidays. No additional mud has appeared since the initial event.

Once a plan has been developed, the final section of the terrestrial bore will be completed and the conduits will be installed.

Over the next couple of weeks, the team will be conducting some additional geophysical surveys to better understand the geological situation so we can develop a suitable path forward. Activity on the sites will be gradually ramping up again as we move into the new year with the focus at Driftwood transitioning to the civil construction and rebuilding the park.

Yesterday, in preparation for the civil construction at Driftwood, the crew started to remove the shipping container wall around on the site to allow for the replacement of the old sidewalks around the parking lot. Note: Driftwood Beach State Park remains closed to vehicles at this time. Pedestrian access to the beach remains open. For safety reasons, pedestrians are asked to keep out of the construction areas.

12/04/21 – At Driftwood, the 30-inch conductor casing that runs along the first 195 feet of the terrestrial bore has been installed. This was achieved by drilling a pilot hole and then gradually opening it up to a final diameter of 38 inches (top left). The casing was then pushed into the hole section by section using the drill rig (top middle), with each new section being welded to the one already in the hole. The bottom of the casing had been plugged with cement before it was installed to stop it from digging into the walls of the borehole. Before drilling could commence, the cement plug was drilled out (top right).

At the end of the day on Friday, 12/3, the crew had pilot drilled 1,130 feet and had reamed 682 feet of this length to a diameter of 22 inches. Drilling and reaming will continue with the aim of hitting the intercept point under highway 101 in the next few days (bottom left).

Drilling at the UCMF end of the terrestrial bore has been completed with the pilot hole running 926 feet to under the western side of Highway 101. All of this has also been reamed to 27 inches. The drill rig has been moved off the borehole and the site is being prepped for the intercept and the conduit pull in (bottom middle and right). We hope this will be completed before Christmas. But there is still a way to go, and things may change.

11/20/21 – Terrestrial drilling operations from the UCMF site towards Driftwood continue (top left). Progress has been slow, but the borehole has now reached the western side of Highway 101, which is where the intercept will happen. The crew are now widening the hole.

Meanwhile at Driftwood, the HDD2 and HDD3 conduits have been grouted in place (top middle) and the mud pits have been filled in until work starts on the vault. The 750 drill rig has been demobilized from Driftwood (top right) and the 440 rig has been moved onto the access road (bottom left) so all the equipment that is no longer needed can be removed from the site.

Today the 440 will be moved back on site and drilling towards the intercept point should start next week. Drilling operations will likely continue through to mid- to late-December. Once the terrestrial conduits are installed, the focus will shift to the civil construction work at Driftwood.

Site preparation at the UCMF is slowly winding down. A culvert has been installed down by Highway 101, conduits have been installed under the highway (bottom middle), and a barn on the property has been demolished (bottom right).

All work has continued despite the recent extremely wet weather. However, the rain has created muddy conditions on both sites and occasionally challenging conditions on NW Wenger Lane. R&G Excavating and The HDD Company are maintaining the roadway as best as they can and will continue to do so until it can be paved. We appreciate everyone’s patience.

11/11/21 – At 2:30pm today, the last section of our offshore conduit was pushed into the ground (Photograph: Diana Worthen, Jacobs Engineering Group). After 163 days of horizontal directional drilling operations, the installation of all four of the PacWave South offshore conduits has been successfully completed. With over 1.25 million lbs. of steel conduit installed, totaling over 4 miles in length, it has been a massive undertaking. A sincere congratulations to all those involved, especially the construction crews who have worked tirelessly for months on end, most recently in extremely challenging conditions, to safely complete this phase of the work. Our focus now switches to the terrestrial bore!

10/28/21 – Some stormy weather on the coast has not prevented the project from making good progress at both the Driftwood site and the UCMF site on NW Wenger Lane.

In spite of the weather, The HDD Company managed to arrange some critically important offshore diver work on 10/19. To make use of a very short weather window when sea conditions were safe for diving operations, Dead Calm Seas had their divers in the water well before dawn. Their verification of the drill punch out on HDD2 and HDD3 was completed by 11am and the dive vessel returned to port before the weather deteriorated once again (top left).

At Driftwood, we are now preparing to install our conduit. We started pushing the conduit into the HDD3 borehole today and hope to be finished this weekend (top middle and right). While we are not planning any nighttime activity during the conduit installation, we are prepared to switch to 24-hour operations if the conduit starts to get hard to push. NOTE: If we need to work late, or work overnight, we will send out an email notification to the neighbors near the Driftwood site. As with our previous conduit push-in operations, only limited equipment is needed so noise levels should not be an issue. However, we will monitor sound levels if we work at night.

Today should also see the start of preliminary drilling operations at the UCMF site. A Vermeer 220 drill rig has been set up at that site and over the next couple of days, the crew will be installing about 200 feet of steel conductor casing, through which they will then drill and ream the borehole down to an underground point near Highway 101 (bottom row). Once that is complete, the American Augers 440 drill rig at Driftwood will drill towards the UCMF and intercept the borehole at the highway.

Also today, R&G Excavating and Seal Rock Water District will be connecting our new waterline to the UCMF location, which also serves some of the neighbors. R&G are also continuing to improve the road and drainage systems and will soon start work at the intersection of Wenger Lane and Highway 101.

10/16/21 – Great progress has been made with our offshore HDD bores at Driftwood since the last update.

Just before noon on Saturday 10/9, HDD2 punched out at the seafloor 5,241 feet away from the drill rig. The following Friday (10/15), HDD3, our final offshore bore, also punched out with a total length 5,170 feet. While this mean that all four of our offshore bores have been successfully drilled, we still need to install the conduit to complete HDD2 and HDD3.

Conduit installation cannot start until divers have inspected the offshore end of the bores and the weather is not cooperating. We are watching the forecast closely and hoping for a weather window so we can mobilize the divers and move to the final phase of the offshore bores.

In the meantime, The HDD Company is beginning to prepare for terrestrial bore between Driftwood and the UCMF property on NW Wenger Lane. Equipment will likely start arriving at the UCMF site in the next day or two and will continue to arrive into next week. This will include some shipping containers to act as sound walls (like we have at Driftwood).

Initial operations at the UCMF site will include the installation of a steel casing, which will run down into the ground. Drilling operations will likely start around the end of this month. As previously mentioned, we will be using the intercept method for the terrestrial bore, with rigs drilling from either end of the bore alignment. However, drilling from the Driftwood end cannot start until the conduit has been installed on HDD2 and HDD3. So the terrestrial bore is also indirectly at the mercy of the offshore weather.

R&G Excavating have been making good progress at the UCMF property and have the site largely finished, most of the roadbed prepared and most of the utilities installed. There is still work to do, but the focus should soon start shifting to the Highway 101 end of Wenger Lane.

10/02/21 – Steady progress has been made with our offshore HDD bores at Driftwood since the last update.

Drilling on HDD2 started on 9/1, and by late on 9/30 the crew had drilled out to 4,940 feet. This is about a week less than it took them to drill out a similar distance on HDD1. The faster progress was expected and was likely due to the drillers having learned valuable lessons during the first bore in terms of the expected material they would encounter and the best mud mix to use. Good mud is key for successful drilling operations, and the project has benefitted greatly from having a specialized mud engineer on site for the first several weeks of operations.

The HDD2 crew are about to start reaming to enlarge the borehole and expect to punch out on the seafloor late next week.

HDD3, our final offshore bore, started on 9/11 and is making similar progress to HDD2. Currently they are at about 3,000 feet.

Significant progress has been made at our Utility Connection and Monitoring Facility (UCMF). The future site of the facility is graded, slopes are riprapped, and the focus has shifted to utility upgrades and road improvements. Unfortunately this work coincided with some significant rain events, which led to some muddy conditions along NW Wenger Lane. However, R&G Excavating put down gravel and rock as needed to keep the lane passable.

The new 8-inch waterline has been installed, and fire hydrants are being installed. The switch over to the new waterline should happen in a week or so.

Other utility conduits continue to be installed alongside the roadway and the road itself is getting graded and rocked. It would have been great if we could have got this done before the rains, but things have improved immensely in the last day or so. A recent addition is a safety barrier along a short section where the lane runs close to a slope.

UCMF site preparation work will continue for a few more weeks. In the next few weeks, The HDD Company will start setting up at the UCMF for the terrestrial drilling between Driftwood and the UCMF. They will be employing an intercept approach where they will drill from both ends and the bores meet in the middle. This will be discussed in more detail when that gets underway.

As always, please be cautious around the construction equipment and construction sites.

09/11/21 – Great progress has been made over the last couple of weeks at the Driftwood cable landing site. HDD4, our southern bore, is now complete and the final conduit has been installed (top row of photos and bottom left). Divers installed check valves on the seaward end of both HDD1 and HDD4 conduits on 9/8 and 9/9. Nothing more will be done with these until we construct the underground vault later in the year.

Drilling has started on HDD2 and, as of the end of the day yesterday (9/10), the crew had drilled just over 1,000 feet of the borehole (bottom middle and bottom right).

Drilling on our final bore, HDD3, is expected to commence today.

08/28/21 – HDD1 is now complete and will be left until the underground vault is installed under the Driftwood parking lot later this year (top left photo).

Divers inspected the HDD1 conduit and the HDD4 drill string out on the seafloor in about 45 feet of water (top middle).

The crews have been busy preparing to push in the conduit on HDD4, which is likely to start early next week. They have also been marking out the alignments of HDD 2 and HDD 3 and are now starting to set up the drill rig for HDD2 (top right). Drilling will likely also start next week. HDD3 drilling operations are scheduled to start the following week.

Site preparation at our Utility Connection and Monitoring Facility (UCMF) located down the highway from Driftwood is progressing well (bottom left and middle). The contractor (R&G Excavating) is currently waiting on electrical conduit before upgrading the utilities and access road to our facility.

Over the last few weeks we have had several visits from Federal, State, and local representatives including Lincoln County Commissioner Kaety Jacobson, Representative David Gomberg and Senator Jeff Merkley (bottom right). It is always a pleasure to show PacWave’s progress to those who have played critical roles in making this all happen.

08/20/21 – Just before 4am today, at the end of the second day of 24-hour operations, the conduit for our northern bore (HDD1) was finally pushed into place (left). The conductor casing that was installed early on is now being removed as it has done its job (middle and right). The next step is for commercial divers to verify the location of the seaward end and to add some additional check valves to ensure the conduit stays watertight until we are ready to install the cables. Once the divers are finished, the drill rig will start on HDD2.

Conduit installation on HDD4 is expected to start in a week or so with a similar operation to what has happened over the last few days. The crew from that rig will then start on HDD3.

08/18/21 – Due to some minor technical hitches, overnight operations are now scheduled for tonight (08/18).

08/13/21 – The extended hours of operation have been postponed as the crew have been setting up for the push in of the final conduit on HDD1. Push in will likely start today and continue over the weekend. Saturday and Sunday nights (8/14 and 8/15) could see overnight push in operations if it is necessary for the conduit to maintain forward momentum. Below is a photo of the crew setting up the tools to connect the sections of conduit together before push in, under an impressive early morning sky.

08/09/21 – Potential Extended Operations on 08/11 and 08/12 at Driftwood. On Tuesday 08/10, we will hopefully start pushing about a mile of conduit into the HDD1 bore hole. There is a risk that the conduit could become stuck if we do not maintain some forward momentum, especially when we reach the curve of the bore path up toward the seafloor. We will get a better feel for this once we start the push in operation.

If a continuous push in is required as the conduit gets further out, there will be a need for some extended hours of operations at our Driftwood drilling site. The current plan is for possible nighttime operations on Wednesday August 11 and Thursday August 12.

The pushing of the conduit will only require the use of a single drill rig and some support equipment. It will not require the use of the on-site centrifuge, mud shakers or mud pumps. As these are some of the louder pieces of equipment on site, we believe that noise generated by the push in operations should have minimal impact to our neighbors. We will be taking sound level measurements to ensure this is the case.

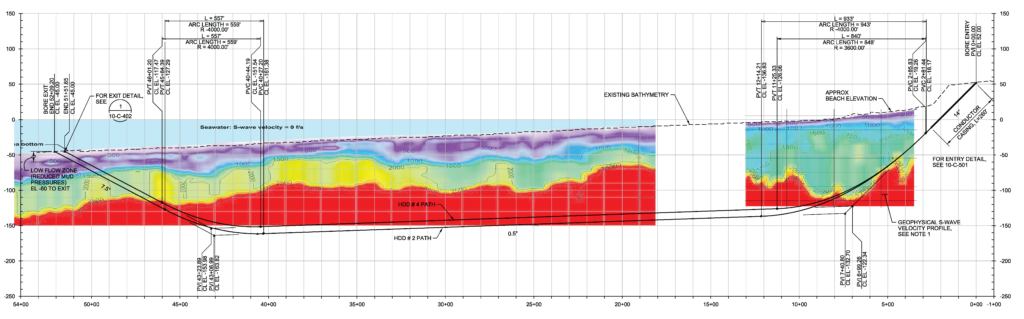

08/06/21 – Below is a figure showing the profile of the offshore bore plan. Our southern bore (HDD#4) has been progressing well and at the end of the day yesterday (08/05), the 12¼ inch pilot hole had reached 4,721 feet. The current plan is to continue drilling out to about 90 feet short of where the drill will reach the seafloor (known as the punch out). At that point, the drilling crew will switch to reaming, or opening up, the whole bore hole to a diameter of 16 inches in preparation for punch out.

Meanwhile, yesterday afternoon The HDD Company successfully punched out our northern bore (HDD#1, left photo) through the seafloor at a distance of over 5,200 feet from the drill rig. The punch out was verified by divers from Dead Calm Seas Marine Services using Billeter Marine’s vessel the Pacific Eagle.

The HDD#1 crew will now start removing the drill string and preparing to push in the PacWave conduit (middle and right photos) that will be left in place and through which the PacWave subsea cables will be pulled at a later date.

Pushing in almost a mile of conduit will likely take several days as the steel conduit has been treated with a special anti-corrosion coating that must not be damaged. The crews may be working longer days to ensure that the conduit goes in smoothly, especially as it gets further offshore. We will keep our neighbors informed about any such activity, although we believe that with the minimal amount of equipment needed for the conduit push in, noise should not be an issue.

07/17/21 – On Saturday July 10, we opened part of the construction site to allow people from the neighborhood an opportunity to see what lies behind the wall of shipping containers. We had approximately 75 visitors, mainly from the immediate area around Driftwood. Mathew Brock of the News Times was there and his article from the July 16 edition has some great photos.

On the drilling front, HDD#1 has been progressing well and the pilot bore is now over 3,500 feet from its entry point in the Driftwood parking lot, and is about 120 feet below the seafloor. While the pilot bore has covered about two-thirds of the total bore distance, it will need to be followed by several passes by larger “hole openers” to enlarge the bore sufficiently to allow us to install the final steel conduit. So, we still have a way to go.

Our efforts to seat the conductor casing on HDD#4 (discussed previously) appeared to have been successful and we recommenced drilling on June 30. However, on July 8, after several uneventful days of drilling, the issue began to reoccur. The drilling contractor, engineers and PacWave Team assessed the situation and concluded that the best course of action was to remove the 250-foot casing to try to determine why it was continuing to not seal well. The casing was removed over the next couple of days (left photo) and the “downhole” end was found to be damaged, perhaps from the pneumatic hammer that had been used on it.

At this point, the team decided to be cautious and abandon the upper section of the HDD#4 bore and start a new bore at a slightly steeper angle. This will allow the drilling contractor to drill down more directly to the harder rock and better embed the downhole end of the new conductor casing (right photo). This process was completed successfully yesterday, and the plan is to drill out and intercept the lower section of the old bore. This should be happening over the next week or so.

06/30/21 – The conductor casing for HDD#4 has been somewhat more difficult to install than the casing for HDD#1. As discussed in the 06/12/21 update, the conductor casing needs to run through the loose material and bed into the deeper rock layer to form a seal that can contain the drilling mud (a mixture of fine clay and water) while drilling operations are underway. Prior to drilling, almost 250 feet of conductor casing was pushed into HDD#4 and down into the rock layer. However, once drilling advanced through the end of the casing, some drilling mud released into the adjacent rock formation and some of the mud made its way to the surface and into a ditch located within heavy brush near the bottom of the slope west of the Driftwood parking lot. Visual monitoring by The HDD Company quickly identified this issue and the location of the mud, and drilling was stopped immediately. Crews then sandbagged the area as a precaution. OSU and The HDD Company personnel are working with staff from the Oregon State Parks, the Department of Environmental Quality and Oregon Department of Fish & Wildlife on a plan to remove the mud once it has dried. The released mud covers approximately an 8- by 20-foot area and is naturally contained in a low point away from environmentally sensitive areas.

A pneumatic hammer system (below left) was mobilized and used to hammer an additional 11 feet of casing down into the deeper rock of HDD#4 to achieve a better seal. This was a loud operation that took place on Monday 06/28. While loud, the operation was short-lived. The HDD Company has since restarted drilling and no further release of drilling mud has occurred. All signs indicate that the downhole end of the casing has been sealed. As a precaution, and while we had the pneumatic hammer on site, we added an additional 20 feet of casing to HDD#1.

06/24/21 — Progress continues. The conductor casing has been installed in HDD#1 (the most northerly bore) and is almost fully installed in HDD#4 (the most southerly bore). One drill rig was out of commission for a couple of days due to a problem with a computer component in the mud pump. Currently spares are not always readily available, so it took longer than normal to resolve the issue. However, everything is operational once again.

06/17/21 — The HDD Company crews have been busy over the last week finalizing the Driftwood site set up and starting to install the conductor casings in the first two bores. Conductor casings are large steel pipes that are installed along the bore path down through the upper layer of loosely consolidated, sandy material to the start of the deeper rock. The conductor casings help stabilize the borehole in this looser material and keep the drilling mud in the hole. Over 200 feet of 18-inch diameter conductor casing will be temporarily installed in each of the offshore bores.

06/09/21 — Site prep at Driftwood continues with more equipment and crew being mobilized to the construction area. The Superintendent and his crew are maneuvering all the various pieces into place and trying to make use of every inch of available space in the parking lot area. As expected, it’s a tight fit. The second drill rig has been set up and the plan is for drilling operations to start at the end of this week.

06/04/21 — The sound wall of shipping containers is complete (the photograph on the left shows the view from the beach), and the first of the two HDD drill rigs is now set up (middle picture).

We received some questions from neighbors about the loud metal pounding that was heard today. This will not be a regular occurrence. The noise happened when the large metal plate shown in the right hand picture was secured in place using the large metal stakes behind it. These are each about 8 feet long and needed to be hammered into the ground to anchor the drill rig. This will happen one more time in the coming days and will be repeated in several weeks when the drill rigs are realigned for the next bores. We apologize for the noise.